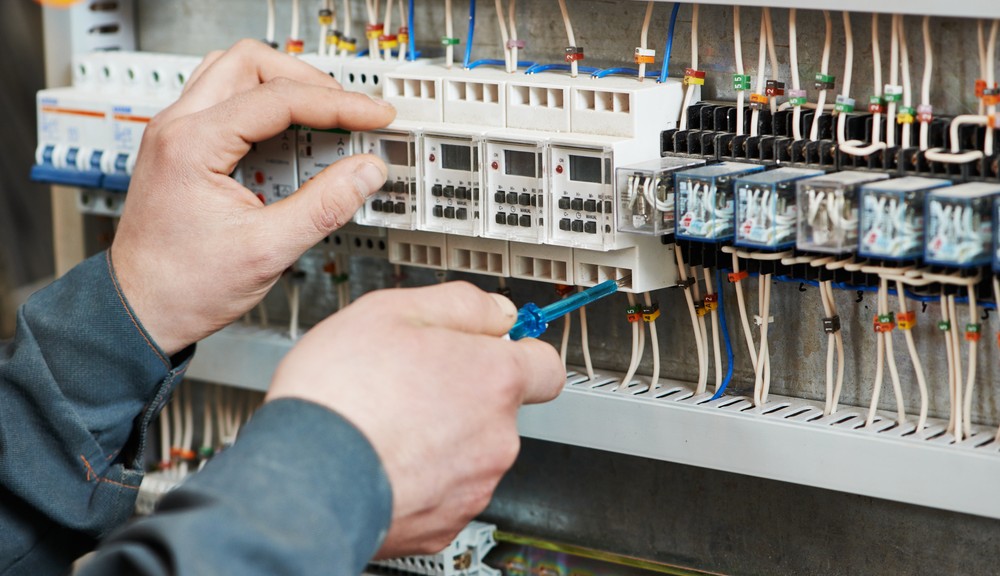

As well as working in homes around Brisbane, the Bevan Robison Electrical team also are your commercial and industrial electricians in Brisbane and can look after all manner of electrical safety inspections for all complex electrical equipment. This is legally required for specialised electrical equipment in a workplace and can only be performed by licensed contractors. This practice is known as testing and tagging.

In this post we explain why this process is so important, how often the procedure should be carried out, and the legal obligations are for business owners when it comes to testing and tagging and maintaining electrical equipment in a workplace.

Why is testing and tagging so important?

Regular testing and tagging involves inspecting electrical equipment to minimise hazards including electric shock and fire hazards. Complex electrical equipment is most often used in a commercial or industrial settings can be dangerous if it is not maintained putting both staff and customers at risk.

Different equipment is grouped into different classes and depending on the class of equipment more frequent testing may be required. After equipment is tested and given the all clear, a tag is placed on the appliance with the test date and the next scheduled inspection and testing date.

What does an electrical inspection check for?

Depending on the equipment, the following electrical in electrical machinery and appliances are inspected and tested:

• Insulation resistance.

• Polarity.

• Earth and current leakage.

• Earthing continuity for electrical grounding.

• Visual inspection of wiring and cords.

How frequently does equipment need to be tested?

Most electrical equipment in an industrial setting should be tested and tagged yearly.

Hired electrical equipment in a business must be tested before each hiring period and then every 6 months after. For the highest voltage electrical equipment (level 3 electrical equipment) a current certificate of conformity when purchased for hire should be included. Make sure to ask for this.

i) Construction Work Equipment – Every 3 months

ii) Manufacturing Work Equipment – Every 6 months is equipment is not double insulated, or every 12 months if equipment is double insulated.

iii) Service Work (commercial cleaning) – Every 12 months

iv) Residential Like Settings Including Hotels – Every 2 Years

v) Office Work Setting – Every 5 years under normal conditions

Your Bevan Robinson Electrical contractor will advise if there are any mitigating circumstances and situations where you may require more frequent testing such as single insulation wires, or if there are circumstances where testing will be sufficient as lesser frequent intervals.

Under Occupational Health and Safety (OHS) laws, it is the company’s responsibility to ensure all electrical equipment is maintained and safe to use, and testing and tagging is the best way to do this to protect your business, and your staff.

To arrange a testing and tagging service for in all work setting for your Brisbane business, call the electrical specialists at Bevan Robinson Electrical today on (07) 3893 2792